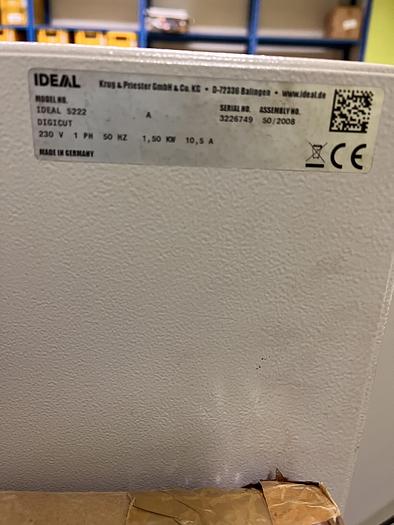

Ideal 5222 Digicut

or

Call +49 2377 / 80 54 820

Specifications

| Manufacturer | Ideal |

| Model | 5222 Digicut |

| Year | 2008 |

| Condition | Used |

| Stock Number | 869568 |

Description

Ideal 5222 Digicut

Side tables right and left, light barriers, program, 1 spare knife,

520 mm cutting length. Electro-mechanical knife drive. Hydraulic drive for press beam. Continuously adjustable

Pressing pressure (min. 200 daN, max. 1100 daN) with display via pressure gauge. Foot pedal for pre-pressing or as cutting line indicator.

Press beam cover. Electrically operated backstop with professional program control. Electronic handwheel

with infinitely variable speed for manual backgauge fine adjustment. Optical cutting line indicator with

bright light-emitting diodes (LEDs). Press beam guided on both sides for even pressing pressure.

Precision backgauge spindle. Adjustable backgauge rake with narrow pitch (32 mm) and plastic glides. Each

Two side stops on the front and rear tables. Solid steel knife holder and adjustable knife guides.

High-quality knife made of quality knife steel. Additional tables (2 pieces) available for an additional charge.

Comprehensive SCS security package:

IR safety light barrier in the working area; transparent safety cover on the rear table; main switch and

Safety lock with key; two-hand cutting release with repeat lock and simultaneity control;

24-volt control; patented IDEAL safety drive; automatic knife and press beam return from any

Position; disc brake for immediate blade stop; blade changing device with covered blade edge;

Blade depth adjustment from the outside; easy blade change from the front, without removing any housing parts.

Electronic control module for the backgauge:

Digital measurement display, measurements in cm/inch (display accuracy 1/10 mm). Direct measurement input via numeric keypad.

Memory operation for chain cuts, additional automatic memory. 99 programs with 99 program steps each (up to 9

Chain dimensions can be saved as a program step). Deleting, inserting and overwriting

Program steps are easily possible. Automatic program sequence when cutting. Automatic set function for

Reference dimension. Paper feed (EJECT) programmable. Two buttons for freely programmable fixed dimensions.

Machine self-diagnosis with error display on the screen.